Project Title:

Small scale processing of silicone slides

Company: Calviri

Description:

Calviri is using standard semiconductor processing machinery which is made of robotic modules for transferring a 12″ wafer between different stages such as spin coaters, bake units, exposure units and wash stations. The issue with such a system is that its designed for mass production scenarios where the process is completely defined and under control. For an startup company where there is a lot of uncertainty and the process needs to be optimized, such a machine has a high operating cost. Each time the machine runs, a full 12″ wafer is utilized and if the synthesis fails, the wafer is wasted. Another issue is that this system is based on standard quartz masks which have a fixed pattern once they are made. Being in the research phase, there happens to be a lot of changes to the mask patterns. The masks are expensive and changing them frequently increase the cost of R&D substantially. Therefore, the company tries to stick to the old designs hoping that the issues with the mask design will be of less concern. This creates problems and adds to the complexity of process optimization.

In an attempt to overcome these issues, I proposed the idea of a machine for small scale processing of silicone slides. The advantages of this machine are:

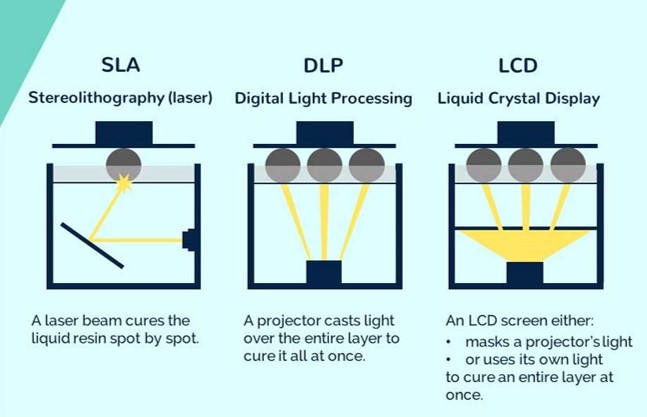

It uses a maskless lithography concept. Different maskess technologies are shown in the image below. In these systems, the patterns are generated through directing the UV light in a controlled was such that only the area of interest is exposed. This can be through a laser beam as in SLA technic, or an LCD in case of this project.

Achievements:

In order to organize the project, the entire system was divided into smaller sub-systems. These sub-systems include: the light processing unit, the coating unit, the wash unit and the bake unit. To simplify the system and reduce costs some critical decisions had to be made. First, the mask aligner was omitted. As a result, the slide is fixed and only moves in a vertical direction during the exposure cycle. The spin coater cannot be used in this scenario because it needs a rotational movement and the slide needs to be aligned after each spin coating cycle. This issue was addressed by using a spray coating system instead of a spin coater. This subsystem is shown in the below video.

The video below shows the spray coating subsystem integrated into the main system: